Product Description:

Flexible Double Containment Piping system

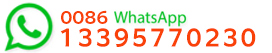

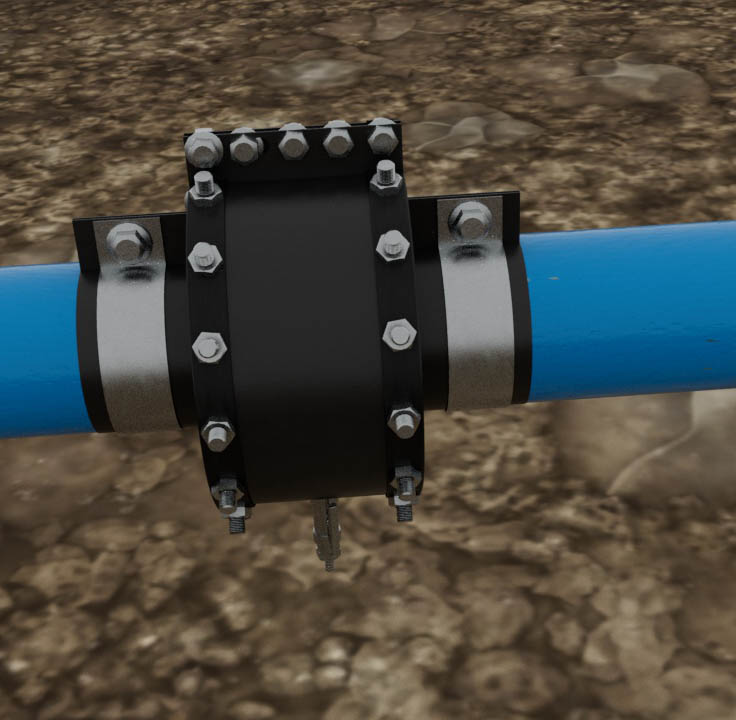

A flexible double containment piping system is a type of piping system that is designed to provide a secondary level of containment to prevent the accidental release of hazardous materials into the environment. It consists of two pipes, an inner pipe that carries the hazardous material and an outer pipe that acts as the secondary containment layer.

The inner pipe is typically made of materials that are resistant to corrosion and chemical damage, such as high-density polyethylene (HDPE) or reinforced fiberglass. The outer pipe is made of flexible materials such as PVC, that can withstand impact and environmental factors. In case the inner pipe fails, the outer pipe is designed to contain the hazardous material, preventing it from being released into the surrounding environment.

Flexible double containment piping systems are common in industries such as chemical processing, water treatment plants, and oil refineries. They can be customized to fit specific applications and requirements, and can be designed to transport a wide range of hazardous materials.

The use of a flexible material in the outer pipe provides additional benefits, such as the ability to absorb vibrations and shocks, which helps to reduce the stress on the inner pipe. In addition, the flexibility of the outer pipe can also make installation and maintenance of the piping system easier and more cost-effective.

Overall, flexible double containment piping systems are an effective way to prevent the accidental release of hazardous materials into the environment. They provide an additional layer of protection that can help to reduce the risk of environmental damage and protect the health and safety of workers and the surrounding community.

Containment piping systems contain fluid that may have escaped via the primary pipeline. hat is a good way to prevent leaking fluid and gas damaged soil.

Flexible double piping systems are relatively low cost and also easy to install to maintain.. in the late 1960s They constructed all kind of flexible materical, such as FEP, PTFE, ECTFE, TPU, EVA, PE, PVC, Three Proof Fabric, non-coated glassfiber with very good durability.

As a supplier of flexible containment piping systems, LCH is uniquely qualified for design steel supports and fabrication along with broad array of steel support options with various flexiblex material selections.

PTFE (Polytetrafluoroethylene) flexible gas leakage cover is a type of protective cover that is specifically designed to prevent gas leakage from pipes, valves, and other equipment used in industrial applications. It is made of flexible PTFE material, which is highly resistant to chemicals and high temperatures up to 500°F (260°C).

The cover is used to protect against leaks that may occur due to wear and tear or damage to equipment. It can also be used preventively to protect against potential leaks in high-risk areas. PTFE flexible gas leakage covers are commonly used in the oil and gas, chemical, and power generation industries.

The cover can be customized to fit the specific size and shape of the equipment it is protecting. It is easy to install and remove, which makes maintenance and inspection easier. Additionally, PTFE flexible gas leakage covers are durable and resist degradation from harsh environments, ensuring long-lasting protection against leaks.

">

You may also like: