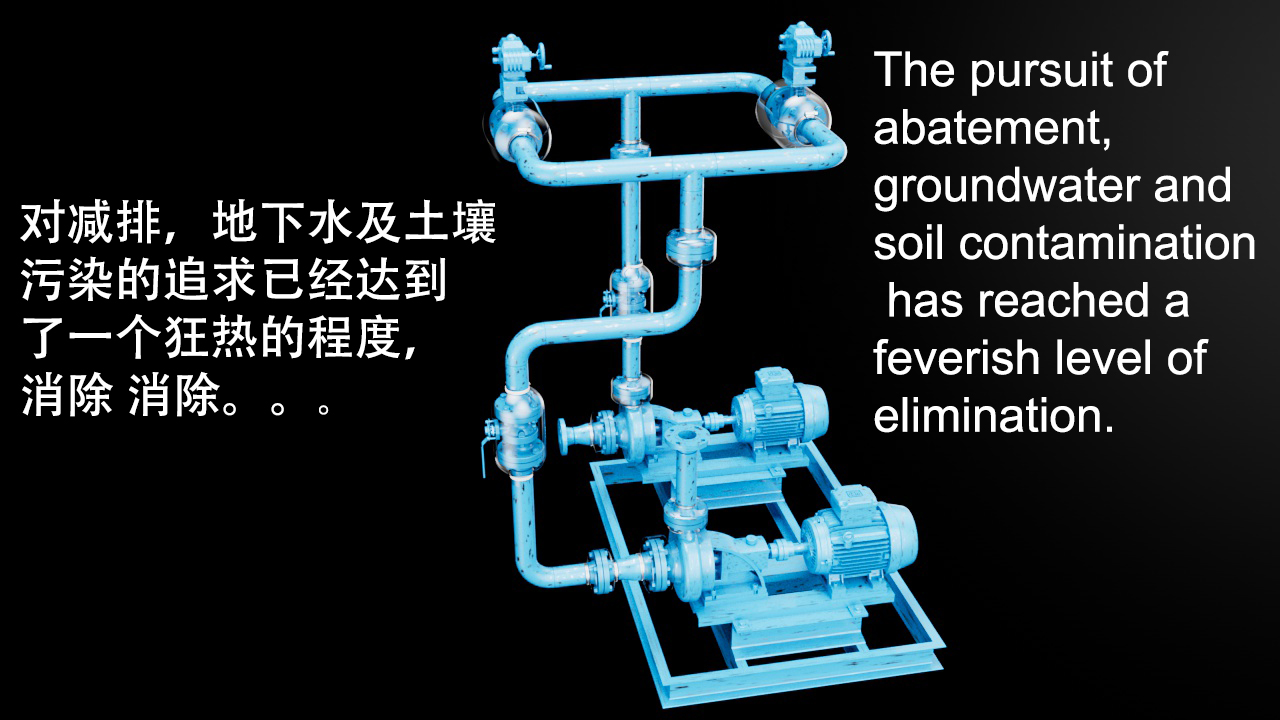

Can LDAR systems be simplified and made safer with zero carbon emissions by incorporating double containment piping technology standards?

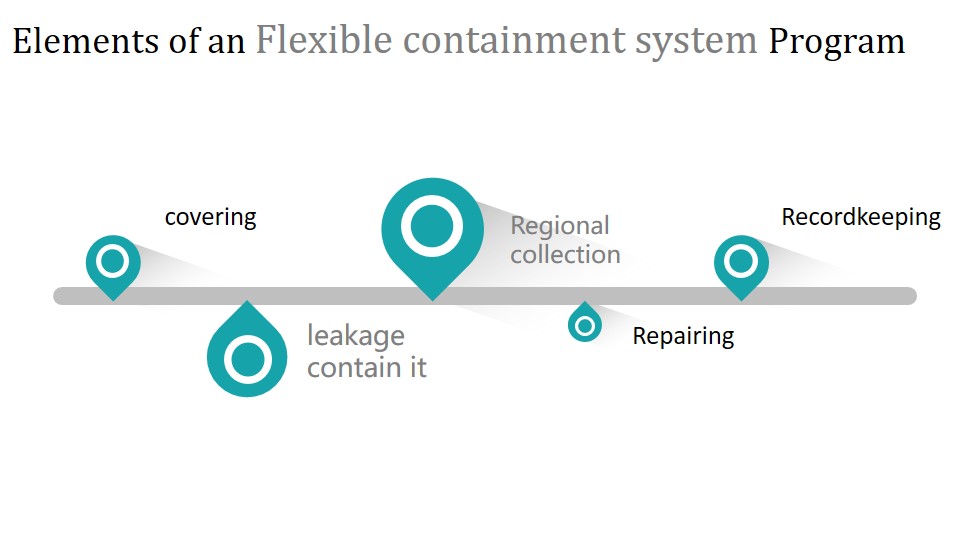

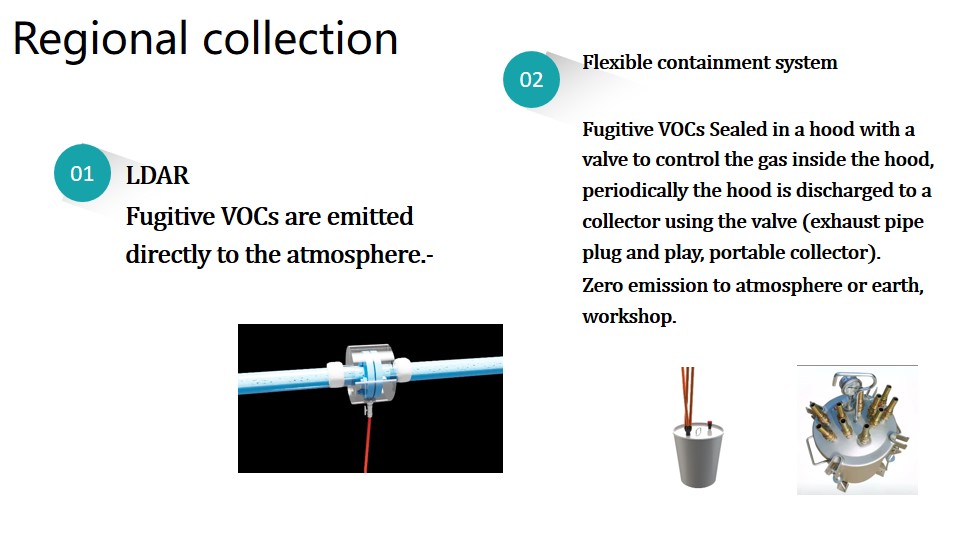

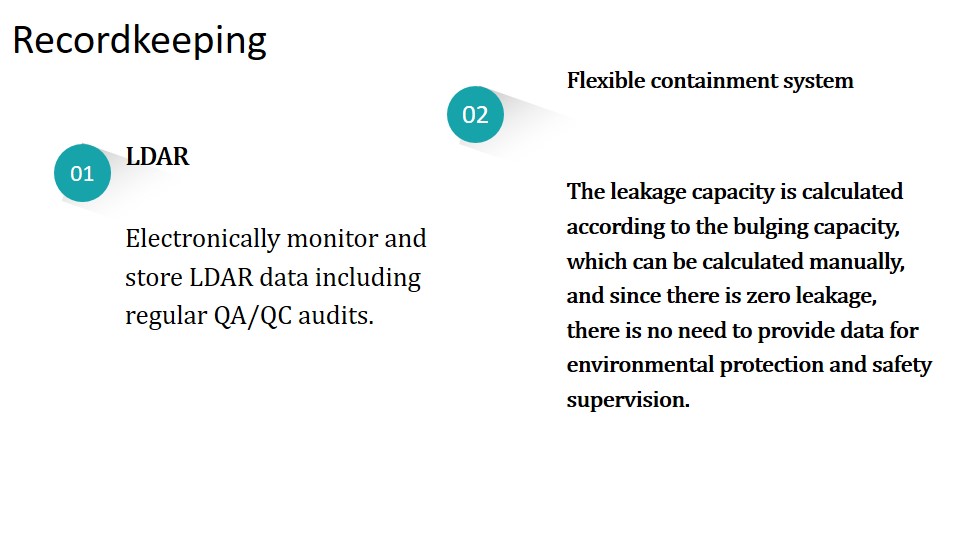

- 1. use internal leakage definitions for valves and pumps in light liquid or gas vapor applications, and monitor according to this uniform definition, including more frequent component monitoring programs, especially those components that have the greatest impact on equipment leakage emissions, is it possible to use sealing covers that are centrally guarded against connections, and regional centralized centralized collection tanks or drums for monitoring, utilizing instrumentation and the ability to What about monitoring and checking the density of leaks on a regional basis, without the need for gas monitoring instrumentation high precision manual testing? Simply visually test the hood for bulging and there is no need to ensure that a QA/QC review process is completed on a daily basis or at the end of each monitoring session for all data generated by the LDAR monitoring technician.

U.S. 40 CFR Part 60 Federal Register :: Request Access

EPA Reference Test Method 21

Method 21 - Volatile Organic Compound Leaks | US EPA

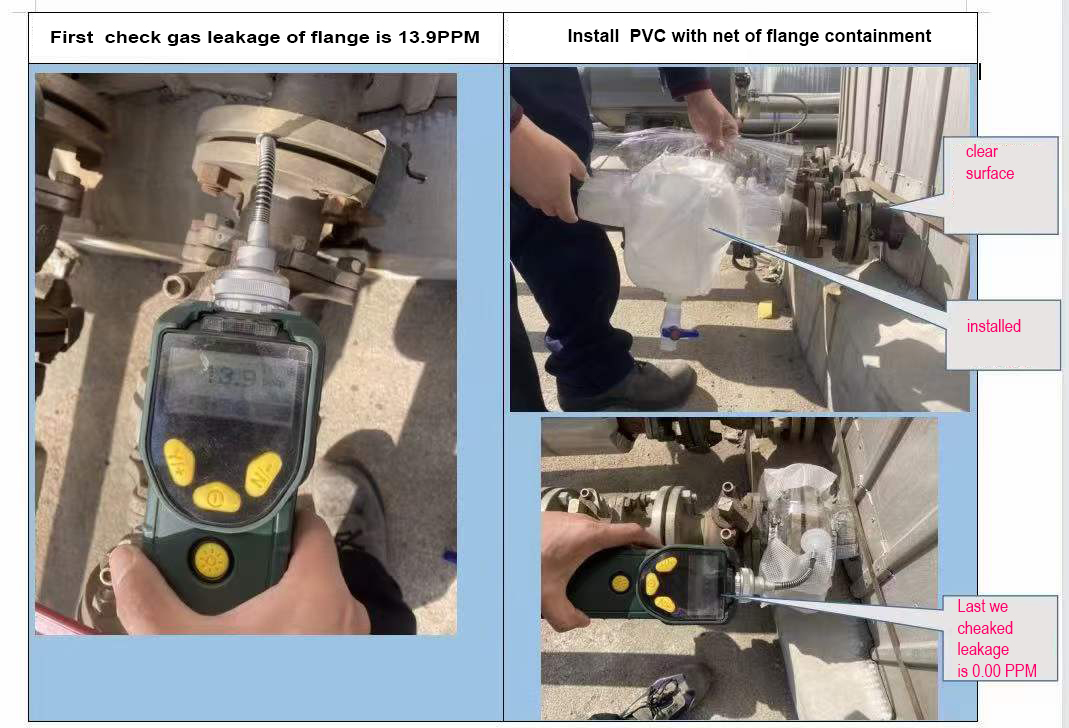

- 2. initial repair within five days and final repair within fifteen days of LDAR leak detection; place any components that cannot be repaired within these timeframes on a delayed repair list for repair during the next downtime cycle Is it possible to seal the leak Cover Covered

In 15-day increments, 15, 30, or 60 days Final Repair.

By hood sealing the joint at the connector, using the U.S. Hazardous Materials Dual Shell Buried Standard technology, slow repair, visual inspection, centralized area instrumentation Is it feasible to replace the LDAR system standard in compliance with the U.S. Hazardous Materials Buried Pipeline Dual Shell Standard, and we're simplifying in simplifying Is it feasible to use the dual shell standard + carnal hood monitoring + centralized collection tank instrumentation Is it feasible to simplify the LDAR system even more, and is it better to meet carbon zero emissions, and is it better to simplify the LDAR system? Whether it is better to achieve zero carbon emissions

What is elements of an LDAR program

What is elements of an flexible containment system program?

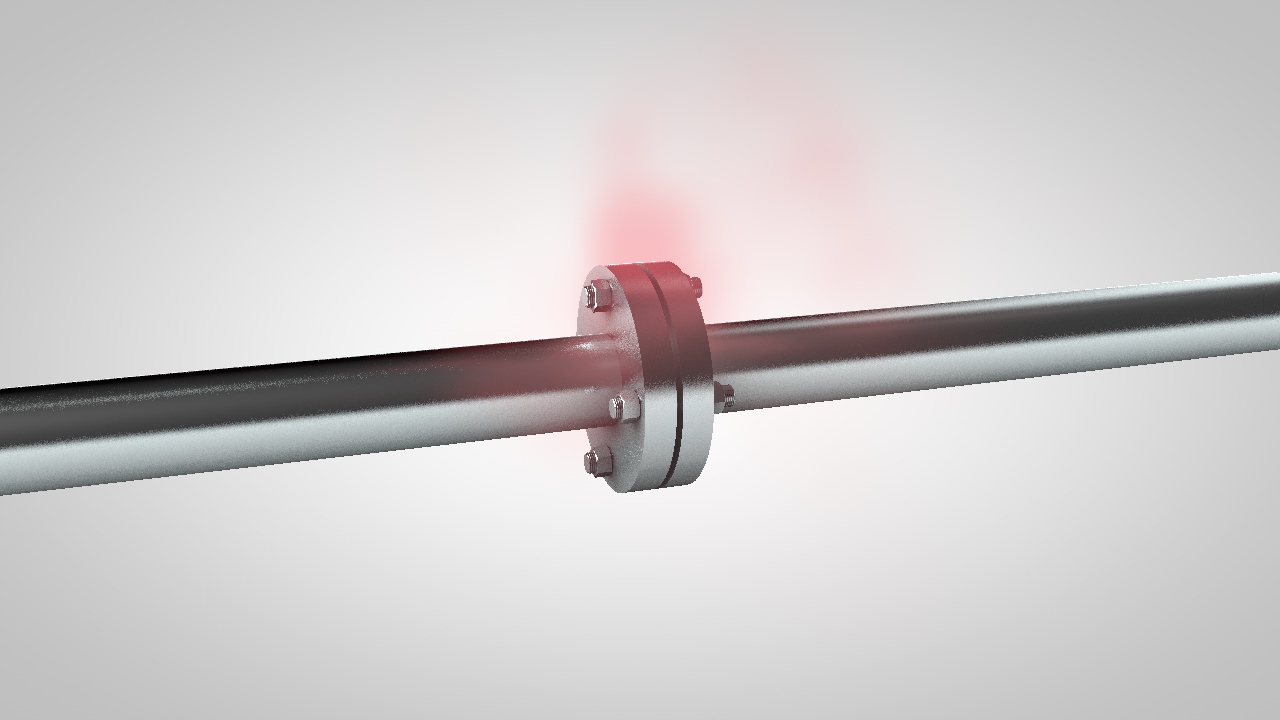

What is pipeline leakage?

Pipeline leakage refers to unintentional leaks or spills from pipelines that transport liquids or gases, such as oil, natural gas, or water. It is a significant issue that can cause environmental damage, harm to human health, and economic losses. Pipeline leaks can be due to various factors such as corrosion, equipment failure, human error, natural disasters, or intentional acts of sabotage. Detecting and repairing pipeline leaks is critical to preventing further damage and protecting the environment. Pipelines are an important mode of transportation for energy resources, but it is essential to maintain them properly to avoid leakage.

Chemical leaks can have serious environmental consequences when they enter the soil or underwater environment. When chemicals like oil or gasoline leak into soil, they can contaminate the soil and the plants and animals that rely on it. In some cases, the contaminated soil may need to be excavated and removed to prevent further damage.

Chemical leaks that enter underwater environments can also have serious consequences. When chemicals like oil leak into water, they can harm marine life, disrupt ecosystems, and damage sensitive habitats like coral reefs. It can take years or even decades for an ecosystem to recover from a chemical spill, making prevention and cleanup crucial steps in protecting the environment.

What is VOCs and oddor fugitive emission

VOCs (Volatile Organic Compounds) are a group of organic chemicals that evaporate easily at room temperature due to their high vapor pressure. They are present in a wide range of products and processes, including paints, solvents, cleaning agents, and various industrial processes. Some VOCs are known to have negative effects on human health and the environment, and can contribute to the formation of smog and ground-level ozone.

Odor fugitive emissions refer to the release of gaseous compounds that produce unpleasant or offensive smells into the atmosphere. These odors can be generated from various sources, such as wastewater treatment plants, landfills, industrial processes, and agricultural activities. The specific compounds responsible for odors can vary widely, but they often include sulfur-containing compounds (e.g., hydrogen sulfide), ammonia, and certain VOCs.

Both VOCs and odor fugitive emissions are considered air pollutants and can pose challenges for air quality management and regulatory compliance. Effective capture and treatment methods are essential for reducing their impact on the environment and public health. This can involve using technologies like adsorption, absorption, biofiltration, and other air pollution control systems to capture and remove these emissions from the air.

Pipelines can cause both soil and underwater pollution

pipelines can cause both soil and underwater pollution when they leak or rupture, releasing the substances they transport into the environment. Some common scenarios involving pipeline leaks or ruptures that can lead to soil and underwater contamination include:

Oil and gas pipelines: Leaks or ruptures in pipelines transporting petroleum products or natural gas can contaminate the soil and, if near water bodies, cause underwater pollution as well. This can have severe environmental consequences, including harm to aquatic life and damage to ecosystems.

Sewer and wastewater pipelines: Leaks or breaks in sewer lines or wastewater pipes can release untreated sewage or industrial effluents into the soil and water bodies, contaminating them with harmful bacteria, viruses, and chemicals.

Chemical and industrial process pipelines: Pipelines carrying hazardous chemicals or materials can cause soil and underwater pollution if they leak or rupture, releasing these substances into the environment.

The consequences of soil and underwater pollution from pipelines include:

Degradation of soil and water quality: Contaminants from pipeline leaks or ruptures can alter the physical, chemical, and biological properties of soil and water, reducing their ability to support life.

Groundwater contamination: Soil pollution can lead to contaminants leaching into the groundwater, posing risks to drinking water supplies and aquatic ecosystems.

Human health risks: Exposure to contaminated soil or water can result in a range of health issues, including skin irritation, respiratory problems, and in some cases, more severe illnesses like cancer.

Ecological impact: Pollution from pipelines can harm plants, animals, and microorganisms that live in or depend on the soil and water, disrupting ecosystems and leading to loss of biodiversity.

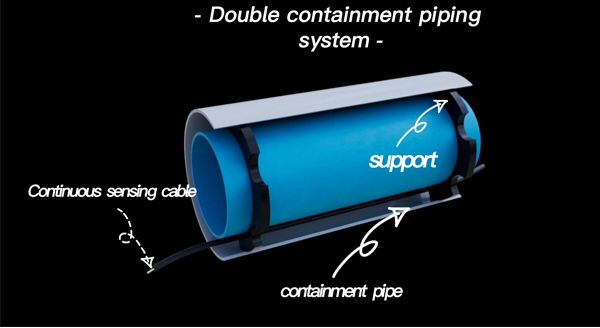

What is double containment piping systems?

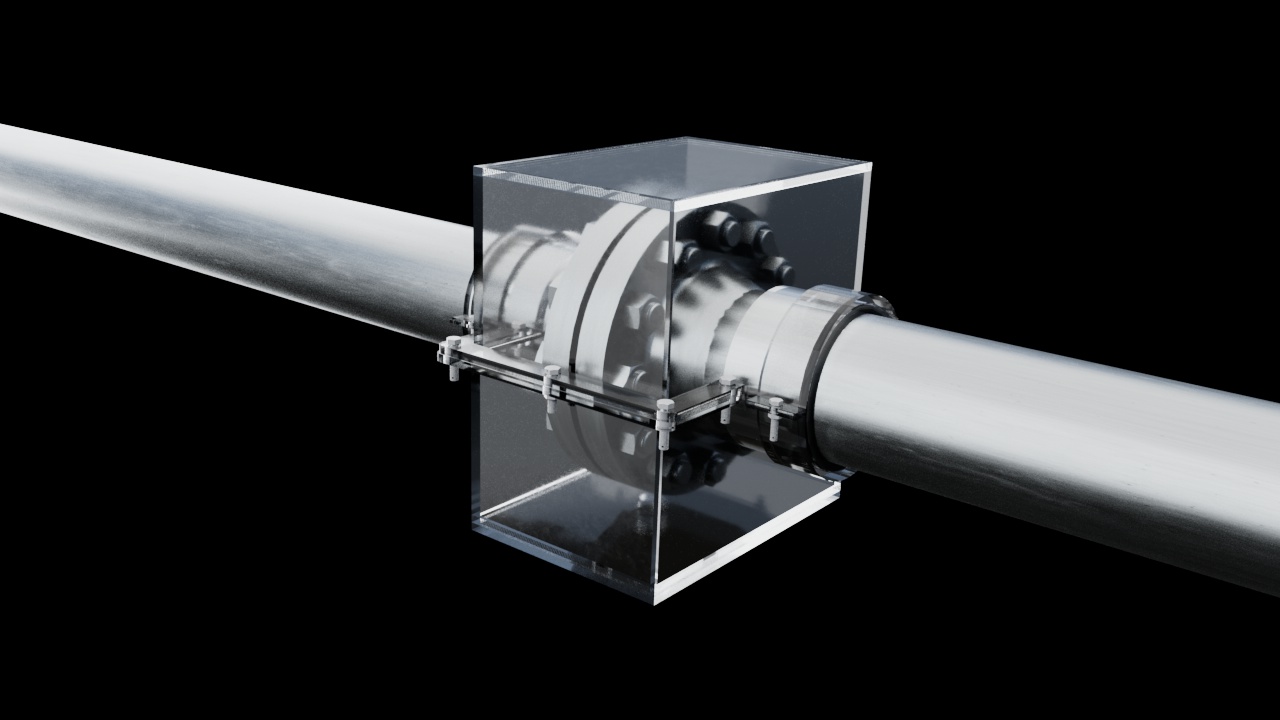

A double containment piping system is a type of piping system that involves two pipes, one inside the other. The inner pipe contains the fluid being transported, while the outer pipe acts as a secondary barrier to prevent

leaks in case the inner pipe fails. The space between the two pipes, known as the annulus, is usually monitored for any signs of leakage or damage to the inner pipe. Double containment piping systems are commonly used

for transporting hazardous fluids such as chemicals, acids, and gases in both aboveground and underground applications. They are designed to minimize the risk of environmental contamination and potential hazards to human

health and safety. Double containment piping systems often require a higher initial cost but will provide cost-effective benefits over time by preventing leaks and reducing the risk of costly clean-up and environmental damage.

What is flexible double(secondary) containment piping systems

What different flanges containment systems from flange spray shields?

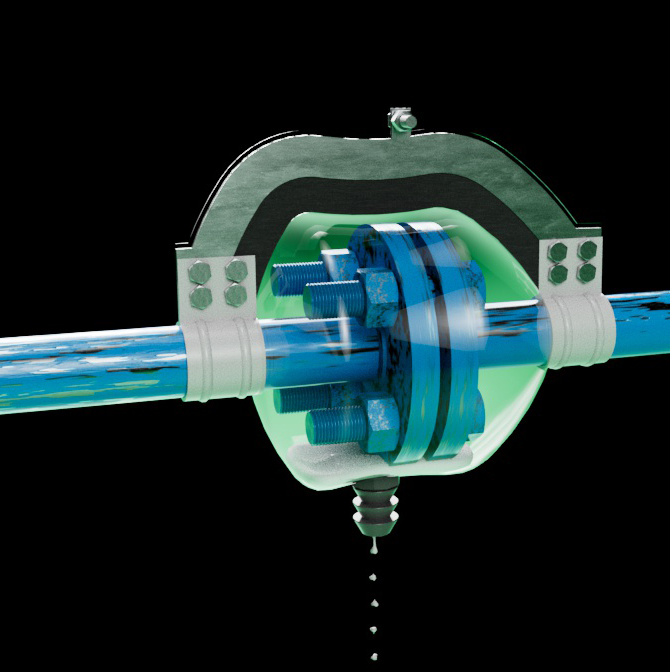

Flanges containment systems and flange spray shields are both designed to protect against flange leaks and spray, but they are different in what they accomplish and how they are implemented.

Flange containment systems are typically designed to control and collect any leaked fluid before it can spread further. These systems usually consist of a containment tray or basin that surrounds the flange joint, along with a drain system that collects any leaked fluid and directs it to a designated disposal area. The containment system is typically designed to work with a specific flange type and size, and is usually custom-made to fit the application.

Flange spray shields, on the other hand, are designed to simply contain and deflect any spray from a leaking flange. They are usually made of a flexible material such as Teflon or fiberglass impregnated with PTFE, and are typically installed over the flange joint. Some spray shields may include a backing material to increase their strength and durability.

Both containment systems and spray shields can be effective in reducing the risk of injury or damage due to flange leaks, but they serve different purposes. Containment systems are designed to prevent leaks from spreading and protect the environment, while spray shields are designed to protect equipment and personnel from the dangerous spray associated with such leaks.

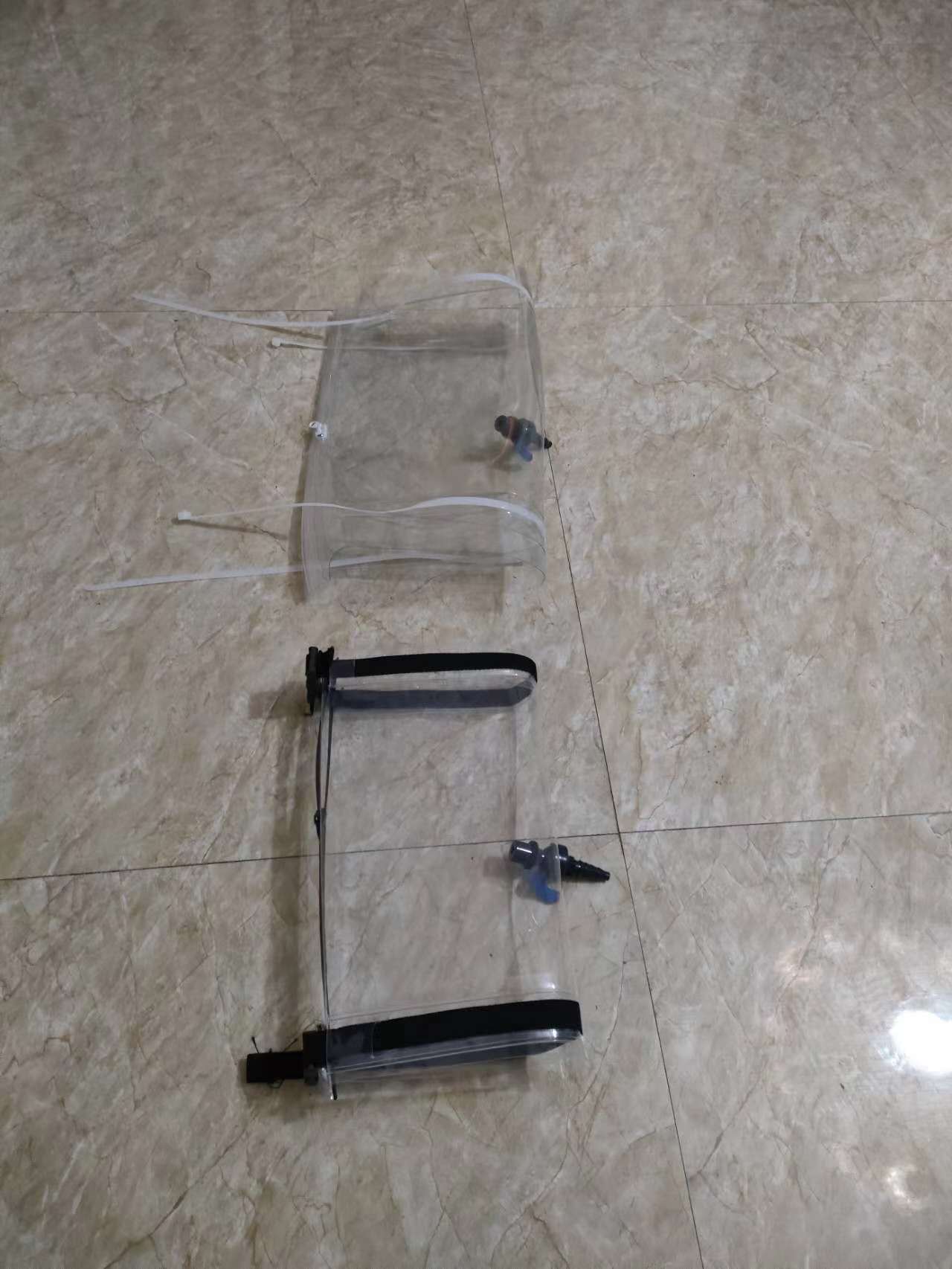

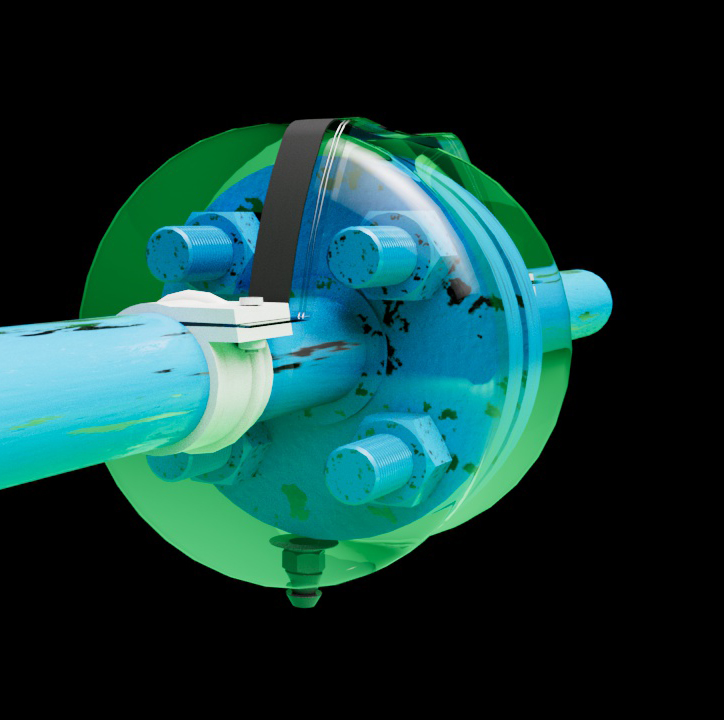

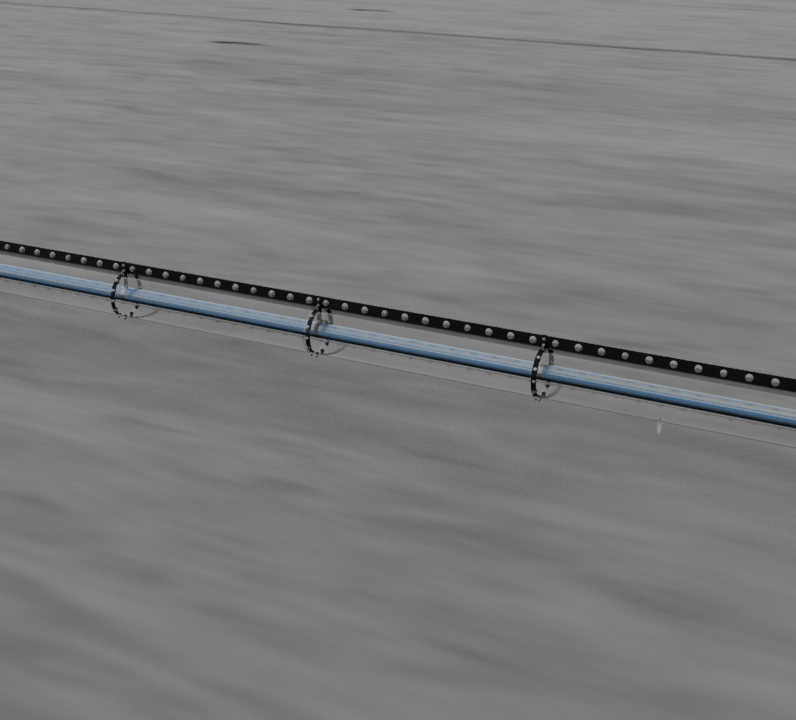

Our Fexible Clear Double Containment is made of transparent EVA/PVC/FEP film,Standward thickness: 0.5 to 2mm

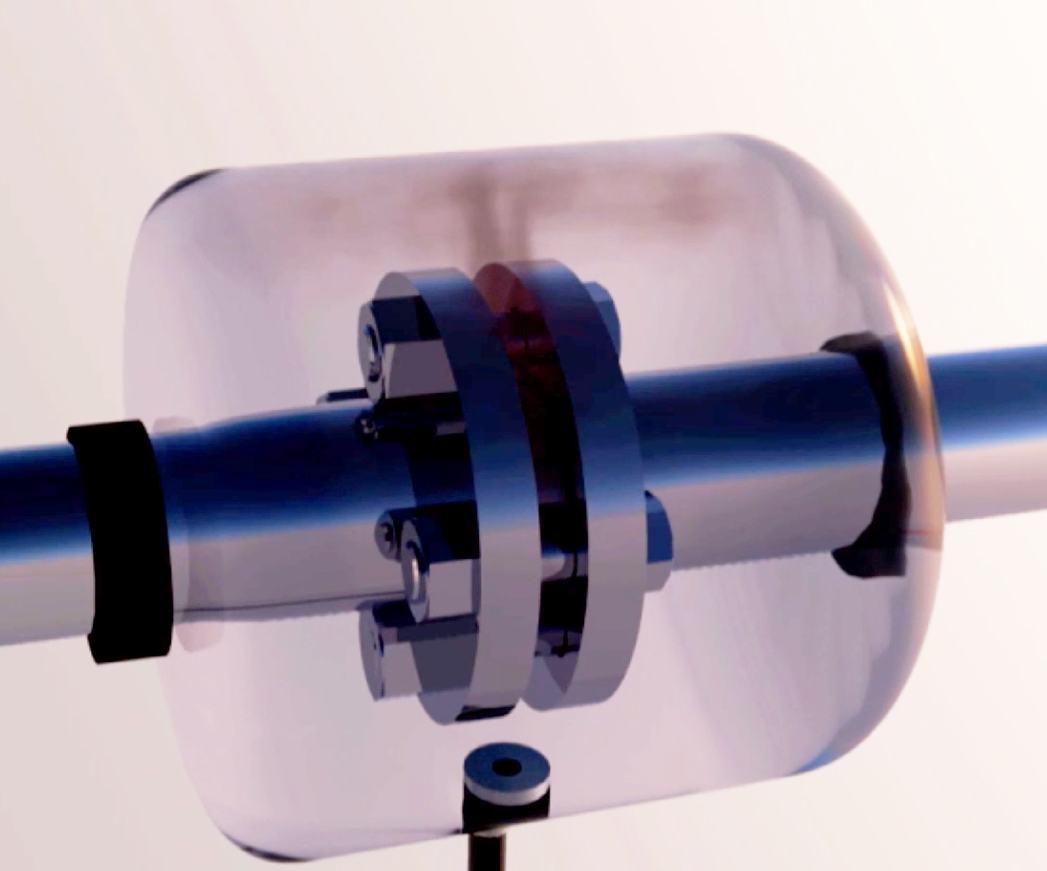

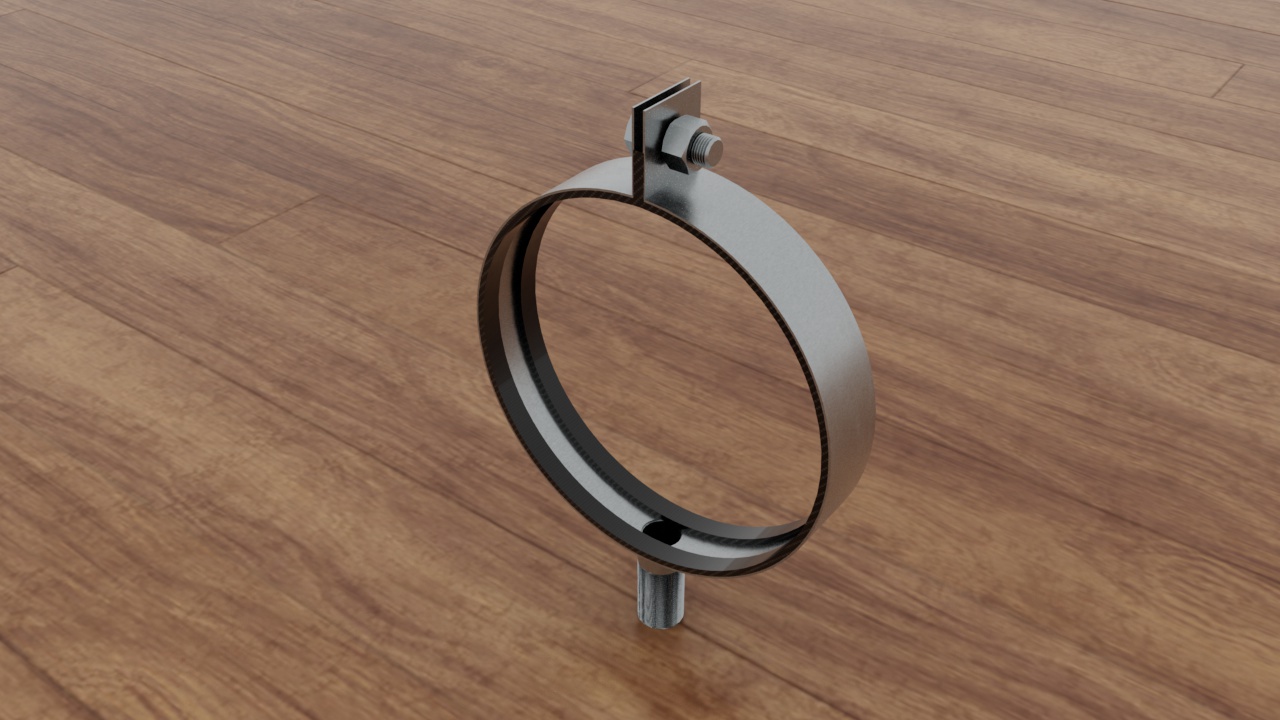

1.Space saving fast and easy installation(Only one standard Clamp with Oring required per end )

2.Lower cost(Up to 80% cheaper than other Double Containment),Lower shipping and storage costs

3.Better versatility & lower flex radius, simpler to handle & simpler to install than current Double Containment products.

4.offer drain,leak detection and drain collector system to meet Environmental Protection Agency (EPA) of outer containment able to retain media transport for a minimum of 30 days required.

Engineered for transferring heating oil, fuel oil, natural gas, chemicals,solvents, process waste, gasoline,jet fuel. power plants,waste collection,water treatment,food and beverage,chemical dosing,pharmaceutical

production,metal,waste water,chemical delivery,life sciences,microelectronics or electrical distribution,andchemical processing.

How to install flexible double containment piping system

It is easy ,Tighten the screw to secure the clamp in place.

1.Let we know flange ,fitting, pipe,valve or equipment size

2. work environment(drug or medical materical is EVA/LLDPE) ,operating pressure and temperature.

3.your logo,can put your logo on flexible double containmnet.

What is different from Clear flexible containment piping system to double containment piping system?

These system are designed for protectiong against leaks of hazardous and gases,They all can be protected environmental .

Double containment pipe also called double wall pipe or dual containment pipe,they only install

at the same time with prime piping install.

install need tool,only used hard plastic double tube.

Clear flexible containment piping system install after prime piping, materical is flexible,no need any tool to install.

cost is low,and clear to confirmation to leakage condition

Options for leakage containment for piping system

Containment piping were developed as a means of containing a fluid which might escape from the primary pipes and preventing a hazardous material from endangering people or contaminating soil, groundwater or air.

Double containment tube

Double containment piping systems are very economical and reliable methods for protecting against accidental or intentional leaks of corrosive or hazardous fluids caused by failure of either the primary carrier pipe or its components. The secondary piping made of Plastic and steel. but these systems most are used in new-built area.

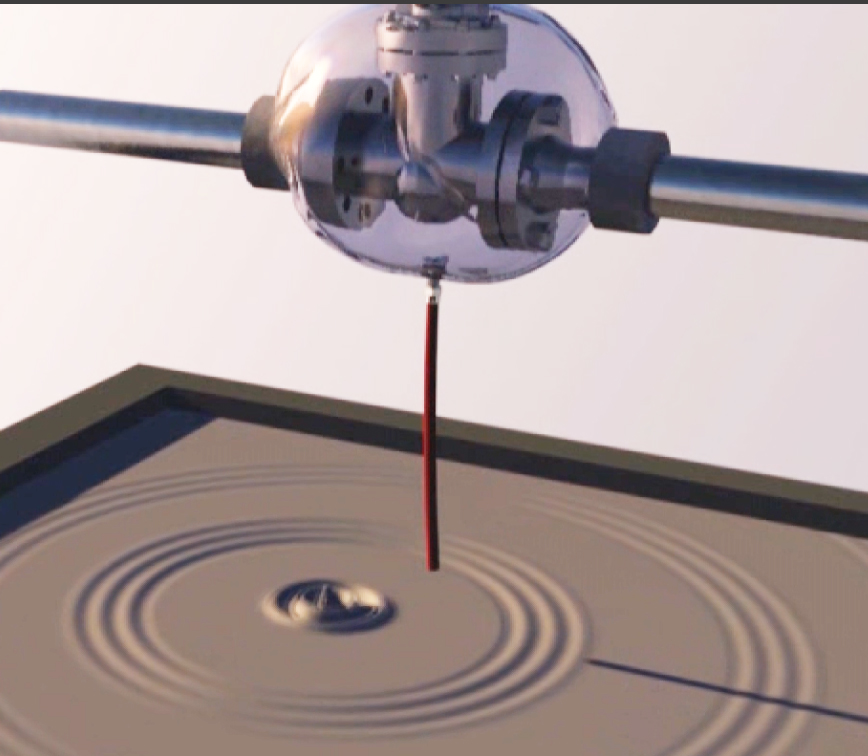

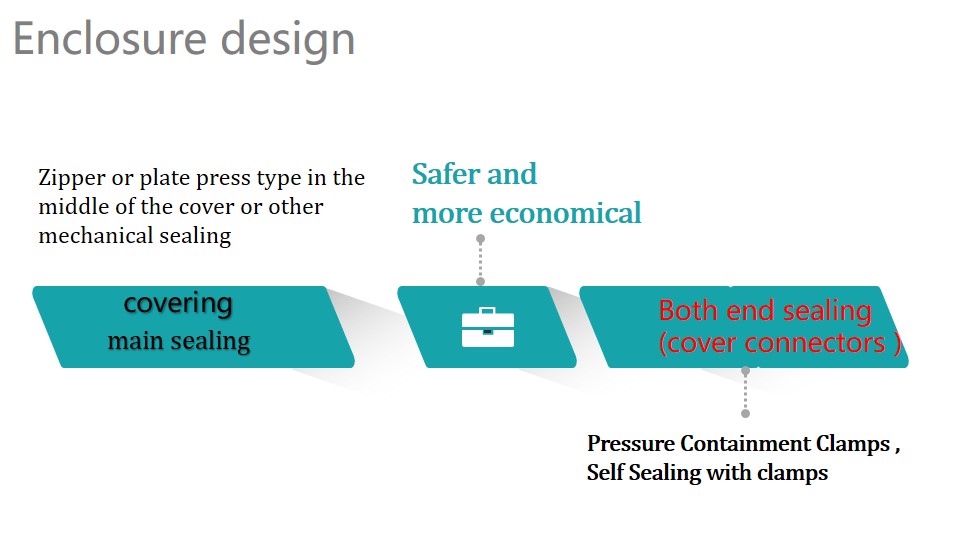

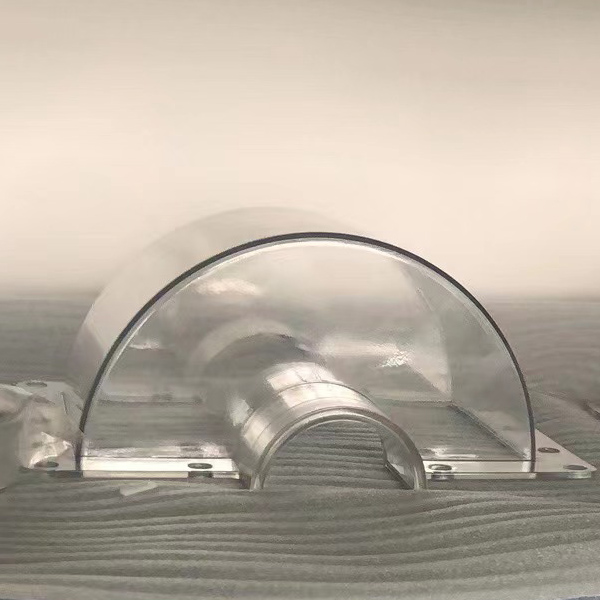

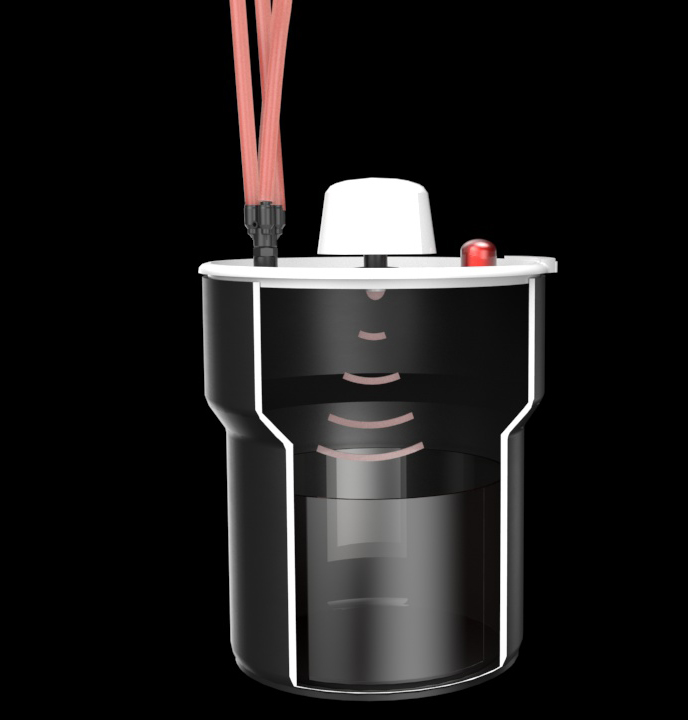

Sealed enclosed containment

It popular approach to preventing overheating is to totally enclose the gasketed/packed area in a tightly sealed enclosure, which is typically capable of withstanding some internal pressure or vacuum from the outside, and thus assuring better control of external leakage from all parts of the body. Available to every kind piping on not only new-built area but also existing area.

Splash guards

Splash guards Constructed of durable sewing of fabrics, These units most by fabric range from easy shields that break sprays without containing them (they will leak out) to units that are moderately contained and can be flush and drain connected which are low priced and adaptable to most sites; their weakness lies in cleaning after leaks, and the risk of them to leak out on their own.

Flexible containment piping system

LCH offers custom-made of PVC,PU,EVA,FEP,ECTFE,PTFE and grassfibres flexible containment fittings, flanges, valve covers, and enclosures which will fit around the valve, flange, or anything. hey may also be subject to dimensional constraints as they can be equipped (at an additional cost) with a purge and drain conduit, leak detection and they may be retrofitted to existing fittings and valves

Seal with zipper or rubber type

Zipper seal

It is characterized by its ability to be re-used and its good sealing performance. It is composed of two plastic teeth that interlock with each other, forming a hermetic seal. The seal can be opened and closed by gently pressing or pulling on the teeth. Zipper seals are typically made of plastic materials such as PVC ,EVA

Rubber seal

A rubber seal is a type of sealing element made from rubber or elastomeric materials that helps to prevent fluids or gases from leaking through gaps or spaces between two surfaces. The seal is typically compressed between two mating surfaces to create a strong and long-lasting barrier that effectively blocks any leakage.

Steel Supports type

Steel Supports type flexible containment piping system similar to sealed enclosed containment,They Constructed of flexible film or fabric,

They are not to dimensional and material limitations.

As we have seen suppliers to Chemical plant, Semi-conductor plant, Oil refinery, Thermal power plant, nuclear power plant and relative facilities, display manufacturing plant have made great strides to reduce leakage of inside liquids from piping piping to air pollution, water pollution, or soil pollution and these pollutions,

For more information: Zhoufuyi (leakcover@outlook.com)

How to prevent Fugitive Emissions of VOC?

Preventing fugitive emissions of VOCs (volatile organic compounds) can be achieved through several approaches:

Equipment Control: Improving production processes, reducing the amount of VOCs used, employing covers, VOC leakage cover seals, precision instruments to track VOC use and emissions, etc. can effectively reduce VOC fugitive emissions.

Waste Gas Treatment: Ensure that waste gas treatment equipment can effectively capture and treat VOCs. For example, centralized control and combustion devices can convert VOCs into carbon dioxide and water to reduce their volatility and effectively control emissions.

Product Substitution: Developing environmentally-friendly products and VOC substitutes can help reduce the use of VOCs and ultimately prevent their fugitive emission.

Strengthened Management: Establishing strict environmental protection management systems and regulations, implementing responsibility systems, strengthening law enforcement inspections and supervision of VOC-emitting enterprises, improving environmental awareness, and increasing environmental investment can all effectively reduce VOC fugitive emissions.

|

|

|

|

|

|

|

|

© 2022 Wenzhou Leakage Corrosion Hardware Products Co., Ltd All Rights Reserved. http://www.leakcover.com ![]()