What caused the leakage of valve and how to prevents the leakage of hazardous materials

I. Leakage from dislodged closing parts.

Cause :

1, poor operation, so that the closing member stuck or more than the upper dead point, the connection is damaged fracture.

2, the closing piece is not firmly connected, loose strength and fall off.

3, the selection of the connection is not the right material, can not withstand the corrosion of the medium and mechanical wear.

Maintenance methods.

1, the correct operation, close the valve can not be too much force, open the valve can not exceed the upper dead center, the valve is fully open, the hand wheel should be reversed a little;

2, the closing piece and the stem connection should be solid, the threaded connection should be backstop pieces;

3, the closure and stem connection with fasteners should withstand the corrosion of the medium, and have a certain mechanical strength and wear resistance.

Second, the packing leakage (valve leakage, the proportion of the packing is large)

Reasons.

1 filler is not selected correctly, not resistant to the corrosion of the medium, not resistant to the use of high pressure or vacuum, high or low temperature valves.

2 filler installation is not correct, there is a small instead of large, spiral coiled joint is not good, tight under loose and other defects.

3 filler over the use period, has been aging, loss of elasticity

4. the stem precision is not high, there are bending, corrosion, wear and other defects

5. insufficient number of packing turns, the gland is not pressed.

6. the gland, bolts, and other parts are damaged, so that the gland can not be pressed.

7. improper operation, excessive force, etc.

8 The gland is skewed, the gap between the gland and the stem is too small or too large, resulting in stem wear, packing damage.

Maintenance methods.

1. should be selected according to the working conditions of the packing material and type.

2, according to the relevant provisions of the correct installation of the packing, packing should be placed by ring pressed, the joint should become 30 ℃ or 45 ℃.

3. the packing should be replaced in a timely manner after a long period of use, aging and damage.

4. the stem should be straightened and repaired after bending and wear, and the damaged ones should be replaced in time.

5. the packing should be installed in accordance with the required number of turns, the gland should be tightened symmetrically and evenly, and the gland should have a preload gap of 5mm or more.

6. damaged gland, bolts and other components should be repaired or replaced in a timely manner.

7. should comply with the operating procedures, except for the impact handwheel, to operate at a uniform normal force.

8. should be evenly and symmetrically tighten the gland bolts, the gland and stem clearance is too small, the gap should be properly increased; gland and stem clearance is too large, should be replaced.

Third, the leakage of the sealing surface

Causes.

1, the sealing surface grinding is not flat, can not form a close line.

2, the stem and the closure of the connection at the top center overhang, incorrect or wear.

3, the stem bending or assembly is not correct, so that the closing member is skewed or not meet in the middle.

4, the quality of the sealing surface material is not properly selected or not selected according to the working conditions of the valve

How to prevents the leakage of hazardous materials

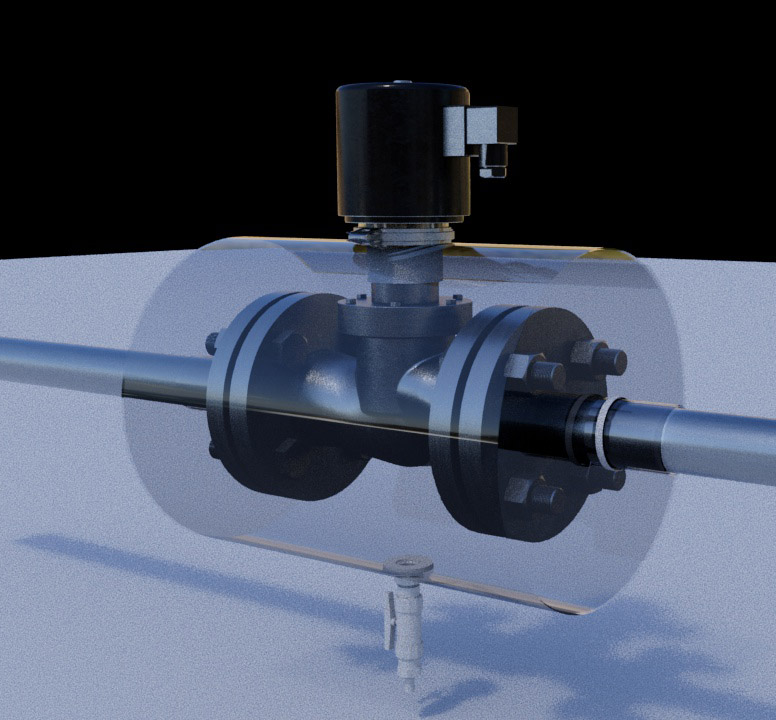

In the market, splash protection is generally used only for valves, where leaking fluid can contaminate floors and damage equipment. Duplex valves are more expensive and troublesome to install

For this reason, we have introduced flexible duel containment valve covers with drainage diversion tubes that can effectively direct the leaking liquid to a collection tank or safe place. Preventing fire and environmental pollution, etc.

Translated with www.DeepL.com/Translator (free version)